Understanding the components of an HVAC system and the role of HVAC basic tools is no longer optional for business owners operating in the heating, ventilation, and air conditioning industry. Whether you manage an HVAC contracting firm, oversee facility operations, or invest in HVAC-related services, having clarity on system components and tools directly impacts efficiency, compliance, and profitability. In today’s competitive landscape, informed decisions are driven by technical knowledge paired with operational intelligence. This guide is designed to explain all about HVAC system functionality in a practical, business-oriented manner. From understanding HVAC all components such as the compressor, evaporator, condenser, and refrigerant cycle, to recognizing how an HVAC technician relies on specialized HVAC tools to ensure performance and reliability, every aspect plays a critical role in service delivery and customer satisfaction. For business owners, HVAC systems are not just mechanical installations, they are revenue-generating assets that demand accuracy, predictive maintenance, and optimized workflows. A deeper understanding of HVAC fundamentals helps reduce downtime, control operational costs, and improve decision-making, especially when integrated with modern HVAC software solutions. This article offers a structured, in-depth explanation of HVAC systems and tools, paired with actionable insights that align with business growth, scalability, and digital transformation. Whether you are expanding your service offerings, training your workforce, or adopting HVAC management software, this guide will serve as a strategic reference point.

Understanding the Components of an HVAC System

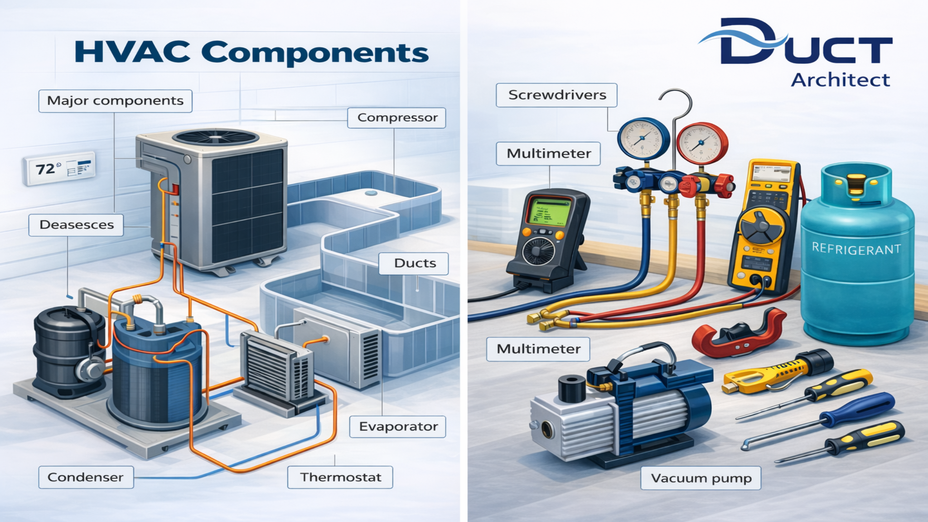

An HVAC system is the backbone of indoor climate control across residential, commercial, and industrial environments. At its core, the system is designed to regulate temperature, manage air quality, and maintain humidity levels to create safe and comfortable indoor spaces. For business owners, understanding the components of an HVAC system is critical for accurate project planning, system sizing, budgeting, compliance, and long-term maintenance strategies.

When discussing all about HVAC system operations, it is important to recognize that HVAC is not a single machine but an interconnected ecosystem of mechanical and electrical components. Each part performs a specialized function, and inefficiency in one component can compromise the entire system’s performance.

From office buildings and hospitals to manufacturing units and retail spaces, HVAC systems directly affect employee productivity, equipment longevity, and customer comfort. Therefore, having visibility into HVAC all components enables business leaders to communicate effectively with technicians, evaluate contractor proposals, and leverage HVAC software platforms for performance tracking and cost optimization.

Modern HVAC systems are increasingly integrated with digital tools, sensors, and automation software. However, regardless of technological advancements, the foundational components remain largely consistent. A strong conceptual understanding of these components ensures better asset management and informed investment decisions.

Key Components of an HVAC System

Below are the primary components that form the foundation of most HVAC systems. Each plays a crucial role in the heating and cooling cycle.

1. Compressor

- The compressor is often referred to as the heart of the HVAC system.

- It compresses low-pressure refrigerant gas into a high-pressure state.

- This process enables heat transfer by raising the refrigerant’s temperature.

- Compressors directly influence system efficiency, energy consumption, and operating costs.

2. Condenser Coil

- Located in the outdoor unit, the condenser coil releases absorbed heat into the external environment.

- As refrigerant flows through the coil, it cools and condenses into a liquid state.

- Efficient condenser operation is essential for maintaining optimal cooling performance.

3. Evaporator Coil

- The evaporator absorbs heat from indoor air.

- Refrigerant evaporates inside the coil, removing heat and lowering indoor temperatures.

- Clean evaporator coils improve air quality and energy efficiency.

4. Refrigerant

- Refrigerant is the working fluid that transfers heat throughout the HVAC system.

- It cycles between liquid and gaseous states.

- Proper refrigerant charge levels are critical for system efficiency and compliance with environmental regulations.

5. Air Handler

- Circulates conditioned air through the ductwork.

- Contains blower motors, filters, and sometimes heating elements.

- Plays a major role in airflow balance and indoor air quality.

6. Thermostat

- Acts as the control interface for temperature regulation.

- Modern thermostats integrate with HVAC software and building management systems.

- Enables scheduling, monitoring, and energy optimization.

7. Ductwork and Vents

- Ducts distribute conditioned air throughout the building.

- Vents regulate airflow into individual zones.

- Poor duct design can lead to energy losses and uneven temperature distribution.

Essential HVAC Basic Tools

To maintain, install, and repair HVAC systems effectively, professionals rely on a defined set of HVAC basic tools. For any business employing or managing an HVAC technician, understanding these tools helps ensure job quality, safety, and service consistency.

Modern HVAC operations combine traditional mechanical tools with digital diagnostic equipment. These HVAC tools enable technicians to work efficiently, reduce error rates, and deliver predictable outcomes, key metrics for business scalability.

Common HVAC Basic Tools Include:

- Manifold gauge sets

- Multimeters

- Vacuum pumps

- Refrigerant recovery machines

- Pipe cutters and flaring tools

- Digital thermometers

- Leak detection devices

Each tool serves a specific purpose and supports compliance with industry standards and safety regulations.

Tools for Installation

Installation tools focus on system setup, configuration, and commissioning.

- Pipe Cutters and Flaring Tools: Used for refrigerant line preparation.

- Vacuum Pump: Removes moisture and air from refrigerant lines.

- Manifold Gauges: Measure pressure levels during system charging.

- Torque Wrenches: Ensure correct tightening of fittings.

- Leveling Tools: Ensure accurate placement of indoor and outdoor units.

Accurate installation minimizes callbacks, warranty claims, and long-term operational issues.

Tools for Maintenance and Repair

Maintenance and repair tools help diagnose issues and restore system performance.

- Multimeter: Tests electrical components and circuits.

- Refrigerant Leak Detectors: Identify leaks early to prevent system failure.

- Digital Thermometers: Measure temperature differentials.

- Airflow Meters: Assess ventilation efficiency.

- Inspection Cameras: Access hard-to-reach components.

Routine maintenance supported by the right tools extends system lifespan and improves energy efficiency.

Conclusion

For business owners operating in the HVAC sector, understanding the components of an HVAC system and the application of HVAC basic tools is fundamental to operational excellence. These elements form the technical backbone of every successful HVAC project, from system design and installation to maintenance and long-term performance optimization.

A clear grasp of compressors, evaporators, refrigerant cycles, and airflow mechanisms enables informed decision-making, better communication with technicians, and improved cost control. Similarly, familiarity with HVAC tools ensures quality assurance, safety compliance, and service consistency across projects.

In a market increasingly driven by efficiency, data, and automation, technical knowledge must be complemented by digital infrastructure. HVAC software platforms, such as those offered by Duct Architect, empower businesses to manage projects, track performance, streamline workflows, and scale operations with confidence.

By investing in knowledge, tools, and technology, HVAC business owners can position themselves for sustainable growth, enhanced customer satisfaction, and long-term competitive advantage.

About HVAC Systems and Tools FAQs

1. What are basic HVAC tools?

Basic HVAC tools include manifold gauges, multimeters, vacuum pumps, refrigerant recovery units, pipe cutters, thermometers, and leak detectors. These tools allow technicians to install, maintain, and repair HVAC systems safely and accurately.

2. How to become an HVAC contractor?

To become an HVAC contractor, an individual typically needs technical training, industry certification, hands-on experience, and proper licensing as per regional regulations. Business owners must also invest in tools, insurance, compliance, and often HVAC software to manage operations efficiently.

3. How to choose an HVAC contractor?

When choosing an HVAC contractor, evaluate experience, certifications, service coverage, response time, pricing transparency, and use of digital tools. Contractors using HVAC software often provide better reporting, scheduling, and accountability.

4. What are the main components of an HVAC system?

The main components include the compressor, condenser coil, evaporator coil, refrigerant, air handler, thermostat, ductwork, and vents. Each component contributes to heating, cooling, and air circulation.

5. What tools do HVAC technicians use?

An HVAC technician uses diagnostic tools, electrical testing equipment, refrigerant handling tools, airflow measurement devices, and digital instruments. These tools ensure precise installation and efficient troubleshooting.

6. How does refrigerant work in an HVAC system?

Refrigerant absorbs heat from indoor air at the evaporator and releases it outdoors at the condenser. This continuous cycle enables effective cooling and temperature control.

Super Admin

Published on January 20, 2026